Scope of Business

Da Vinci's core technology is thermal system design. Our main business is contracted development, primarily on conductance and radiation of heat, thermal energy conversion (the electrical generating system by the temperature difference), and so on. One example of our products is the dual Peltier module, which is used as a cooling element with dehumidifying structure and an element of thermal energy conversion.

Da Vinci plans to manufacture and sell the RHE, which converts waste heat and solar heat into electricity. And our main objectives are slowing global warming and promotion of renewable energy. Now we are planning to promote the resinization of products for Rotary Expander (the RE Expander; the main component of rotary heat engine), and aiming to reduce the price. Also, we are expanding the license of our own patent to overseas companies and the system of RE Expander agency.

Development

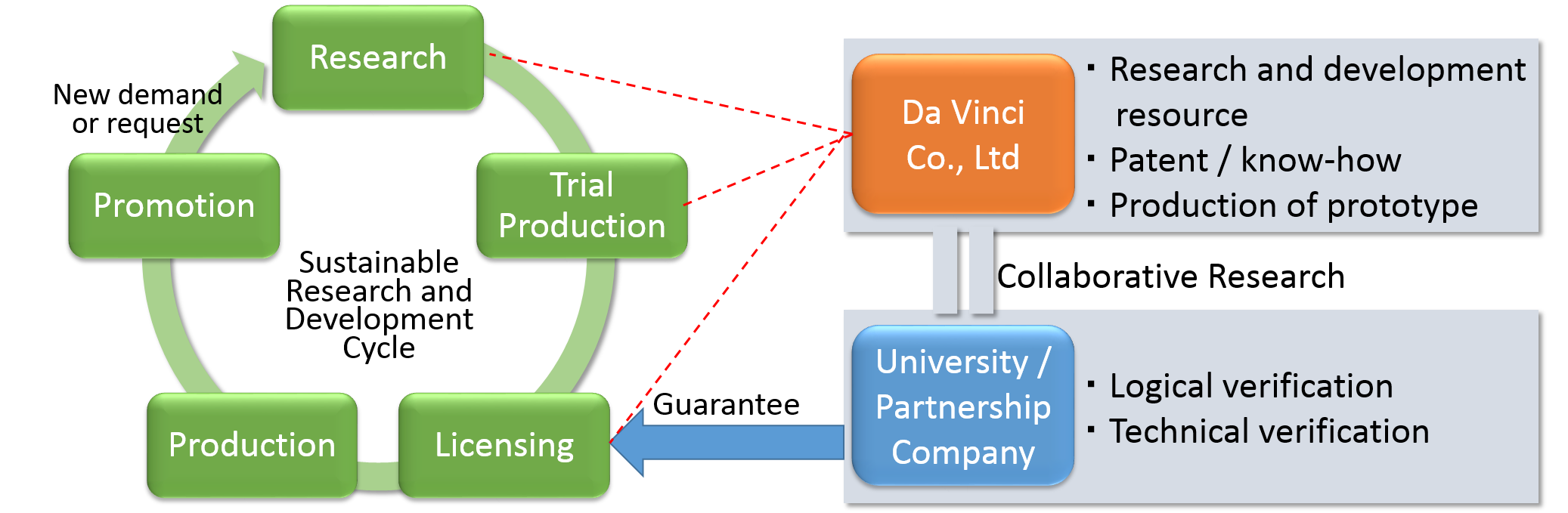

The figure below shows how we develop our technology. We develop our certified technology by evaluating logically at university and verifying technically at partnership company.

Contract development

Achievement

Dehumidifier, Seebeck generation unit, EGR cooler, CPU cooler, EL display equipment and invertor, Natural convector, etc.

※Thermal design support is available to help you solve thermal problems. (Charged)

Basic Information

| Date of Foundation | April 1, 1989 |

| Capital Fund | 10,000,000 JP Yen |

| President | Kenji Higashi, CEO |

| Mission | Great products which contribute to society |

| Objective | Commercialize technologies that use heat effectively |

| Business Locations |

|

| Collaborative Development |

|

Facilities

- A modeling machine that can create three-dimensional models from 3D CAD data.

- Constant temperature and humidity laboratory where various experiments can be conducted by maintaining the room at constant temperature and humidity.

- Thermography capable of charting image data, visual images, average temperature, line analysis, etc.

History

| 1989年 | Apr. | Established Yook International Co. On October 31 of the same year, acquired travel agency registration (Minister of Transport Registration General Travel Agency No. 6182). At the same time, the company began secondary wholesale of overseas travel products. |

| 1991年 | r. Kenji Higashi began experimenting with simple steam sauna products. | |

| 1992年 | Sep. | We developed a simple steam sauna product, version 1, and filed a patent application. |

| 1994年 | We received an order for developing additional products from Dainihon Jochugiku Corporation Limited. | |

| 1995年 | We applied for an international patent for Steam Sauna Type 2. We also used for a patent to improve water quality and soil with microorganisms. We applied for a patent jointly developed with Dainihon Jochugiku Co., Ltd. | |

| 1996年 | We began to sell steam sauna 'Florida,' targeted an IPO, and appeared on the Kansai Technology Map published by the Kinki Ministry of International Trade and Industry as Venture Enterprise. | |

| 1998年 | Our sauna patent application was registered, and we were granted an exclusive license. The company name was changed to Da Vinci Corporation Limited, and headquarters were moved to Yamato-Takada (current location) from Osaka. | |

| 1999年 | We targeted to develop heat-to-electricity converting devices and began to manufacture Peltier style CPU cooler, and delivered it to Toshiba Fuel Cell Power System Corporation. | |

| 2000年 | Head Office and Research Center were integrated and relocated to Yamatotakada City, Nara Prefecture, and started manufacturing Peltier CPU coolers delivered to Toshiba Fuel Cell Systems Corporation. | |

| 2001年 | The development of a non-contact temperature control device using a radiation thermometer was commissioned by Noritsu Koki Co. Microcomputer control by various sensor inputs was adopted for Peltier type coolers. | |

| 2002年 | We were commissioned to develop a new type of Peltier device and applied for a patent. In addition, we started to create applications of side-chain crystalline polymers and inverters for EL (electroluminescence). We also developed three types of forced-air Peltier coolers (60W, 120W, and 240W) and a self-excited type as coolers for industrial equipment and delivered them to Denso Corporation. | |

| 2003年 | Started development of a two-stage Peltier element with a unique shape and succeeded in producing a prototype with a thermoelectric conversion efficiency of over 70%, which is scheduled for commercialization in 2005. Developed a thermally controlled adhesive cleaning tool with a high sanitizing effect using a side-chain crystalline polymer (Intellimer). | |

| 2004年 | The mass production prototype of the two-stage Peltier module was commissioned to Ferrotec, and manufacturing was started. We also commissioned research and development of a Peltier-type dehumidification structure from As One. We started joint research with the University of Tokyo on heat transfer elements and applied for a patent. | |

| 2005年 | The two-stage Peltier module was adopted for the dehumidification structure of physical and chemical equipment, and we started manufacturing it. In addition, a prototype of a heat transfer device (magnetic heat pump), which is a joint research project with the University of Tokyo, was manufactured, its performance was verified, and magnetic field analysis and fluid analysis were conducted. As a new research subject, we started research on a temperature difference power generation device using exhaust heat in collaboration with the University of Tokyo and applied for a patent. We also concluded a joint research agreement with Kansai Electric Power Co. on the temperature difference power generation system. | |

| 2006年 | We obtained venture capital 30,000,000 JP Yen from Mie Prefecture and Opened a research laboratory at Nabari, Mie. We also started to lead Ondosa Hatsuden Kenkyu Kai (a research group focusing on Temperature Difference Power Generation), supported by the Neo-Cluster forwarding community (Minister of Economy, Trading, and Industry, METI). | |

| 2007年 | Mar. | The company increased its capital by 25 million yen and its capital reserve by 25 million yen, for a total of 50 million yen, through a debt-equity swap. |

| 2007年 | Nov. | We increased our capital to 60,000,000 JP Yen through a dead-equity swap and obtained an investment from Future Venture Capital (JP venture firm). |

| 2008年 | Mar. | We opened The European office in Brussels, Belgium. |

| 2008年 | Apr. | We established a European office in Brussels and Belgium. In addition, we opened the STEP (Socio Thermal Energy Project) Laboratory at The University of Tokyo. |

| 2009年 | Jun. | We have completed Rotary Heat Engine (500W size) product in June. |

| 2010年 | Feb. | He was awarded the Kansai Front Runner Award. |

| 2010年 | Jun. | We received Kansai Front Runner Grand Prize in February. We have completed the Rotary Heat Engine system (1kW) in June. |

| 2011年 | Apr. | Ministry of the Environment in Japan decided to sponsor our research on the Rotary Heat Engine in April. We have completed the Rotary Heat Engine (10kW Commercial Model) in May. |

| 2011年 | May. | A practical model of a 10kW Rotary Heat Engine has been completed. |

| 2012年 | Apr. | In April, RIKEN and Da Vinci established a new team (Radiant Energy and Electricity Generation Research Team). |

| 2013年 | Jan. | TV Tokyo broadcasted the Rotary Heat Engine in January. We have established Green Energy LLC in March. |

| 2013年 | Mar. | Established Green Energy LLC. |

| 2014年 | Apr. | Started order acceptance of 10 kW RHE in April. |

| 2015年 | Started development of plastic RE (Rotary Expander) for decreasing cost | |

| 2017年 | Nov. | Kawayu-no-Mori Hospital (Hokkaido) begins grid connection for low-temperature geothermal power generation at 56°C. |

| 2018年 | The Rotary Heat Engine is featured in the Image of Hydrogen Utilization under the Theme of Osaka-Kansai Expo 2025. (Konkei Bureau) | |

| 2020年 | Started development of RE aero-derivative power generation unit (Kunipro) and created wave power generation. |